Smith's Products

Polyurethane

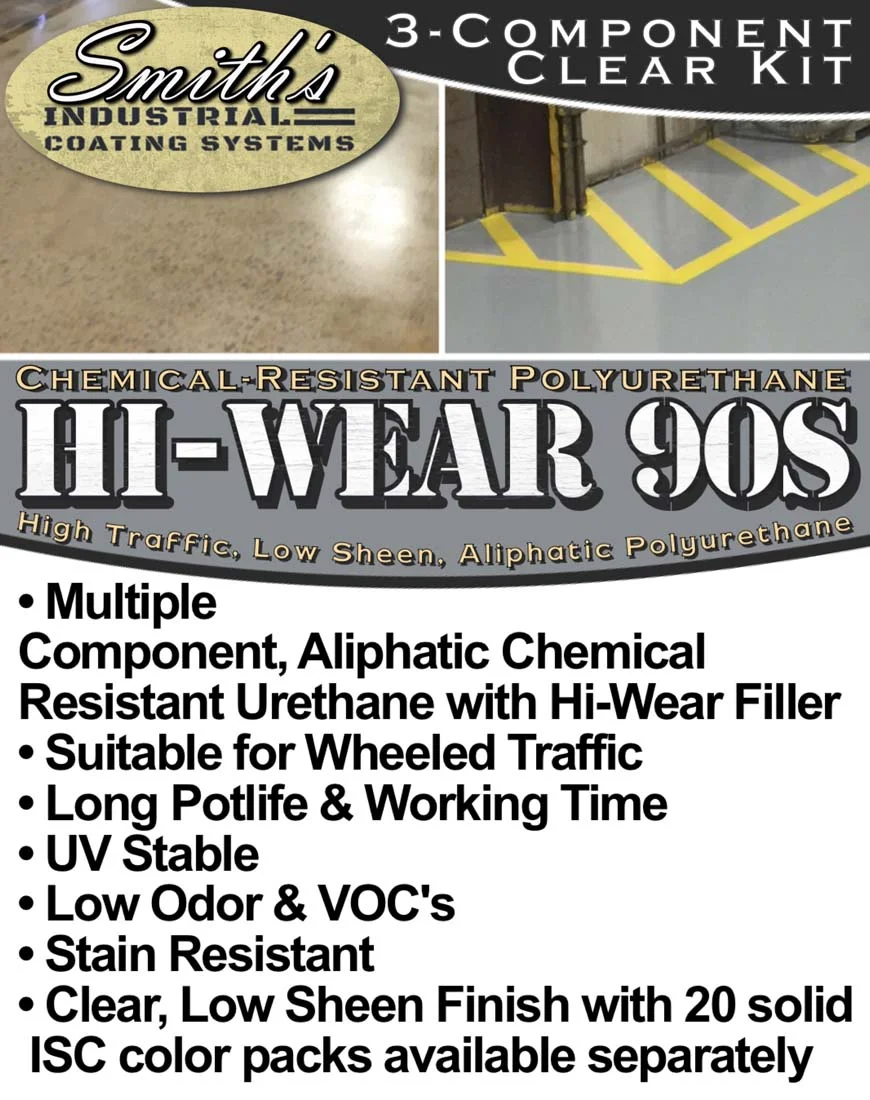

Hi-Wear 90S

High Traffic CRU| Product Quantity | 1.15 gal |

| Colours | Can Use ISC Or Pigment Pods |

| Working Time | 3 Hours |

| Pot Life | 3 Hours |

| Dry Time | 6 Hours TF | 24 Hours FT | 40 Hours HFT | 10 Days FC |

| SF Or LF | 830 SF | 550 SF |

| Area Or Depth | 2 mils/unit | 3 mils/unit |

| Floor Or Wall | Floors |

| Interior or Exterior | Interior |

| Hardness (Pencil) | 3H |

| TF | Tack Free |

| RC | Recoat |

| FT | Foot Traffic |

| LT | Light Traffic |

| DT | Dry Through |

| FC | Full Cure |

| HFT | Heavy Foot Traffic (Forklift) |

| VT | Vehicular Traffic |

| FUT | Full Traffic |

-

Smith’s Hi-Wear 90S is a low sheen finish, Aliphatic, 3-component clear or 4-component pigmented chemical resistant 90% CRU for use in high traffic environments needing a highly durable, chemical & abrasion resistant U.V. Stable topcoat

-

Can put over PASP; can go in cooler as long as cooler is turned off to apply, needs a base layer & will be slippery

-

RECOMMENDED USES (including but not limited to): Avionics & Hangar Floors; Food & Beverage Floors; Forklift traffic areas; Heavy Industrial Manufacturing areas; Pharmaceutical Floors; Vehicle Assembly & Service areas; Healthcare & Veterinary as topcoat over resinous flooring

-

HIGHLIGHTS: Developed for heavy traffic and abusive environments; Greatly improves the service life of the coating system; Resists development of traffic patterns and finish dulling; Excellent rolling load resistance to forklift traffic; Improves light reflectivity; Easy to clean; Chemical resistant to most alcohols, caustics, fuels, oils and solvents; Meets FDA Food Code – Physical Facilities 6-101.11 Surface Characteristics. Not tested for CFR 21 Direct Food Contact.; Overnight return to service

-

LIMITATIONS: For industrial & wheeled traffic/fork lift traffic conditions, a minimum of an ICRI CSP 3 profile is required for mechanical preparation as well as underlying resinous system; Does NOT block U.V. light when applied clear over a non-U.V. Stable product (i.e. Epoxy); NOT water clear - may discolour underlying layer when applied clear; Foaming possible when over applied (too thick); Do NOT install coatings when the Dew point is within 5° of the temperature.; Application is NOT recommended above 80% at time of install; Priming is highly recommended when applying over porous surfaces as the liquid may absorb too much leaving the powder filler loose on the surface. A mock-up should be installed if a single coat of Smith’s Hi-Wear 90S is desired direct to bare concrete to determine the absorption prior to proceeding with the installation

-

NECESSARY TOOLS and EQUIPMENT: Plastic Sheeting or Ram Board to cover floor for mix station; Paint mixing paddle; Low speed ½” drill (Variable Speed ≤450 RPM);+ 5 gallon Plastic Mixing Buckets; Premium, Non-Shed ¼” or 3/8” Nap Paint Roller Covers; Several 18” wide, non-metallic Paint Roller Frames; Wide paint trays (for dip & roll applying); Multiple Extension Poles; Cleaning Solvent (Acetone, MEK, or Xylene)

-

Smith’s Hi-Wear 90S is strictly a finish topcoat product intended for no more and will blister if applied too thick. Any imperfections, sanding marks/swirls, scratches, gouges, etc. that can be felt by hand or catch a finger nail when pulled across the area in the prior layer may transfer through this finish due to the minimal thickness of Smith’s Hi-Wear 90S in a single coat application. Surface defeats are purely aesthetic and pose no threat to the long term performance of the coating system. Once mixed, immediately pour Smith’s Hi-Wear 90S into a tall paint tray, such as a Wooster® Wide Boy™ 5 gallon paint tray. DO NOT POUR Smith’s Hi-Wear 90S onto the floor and spread! Dip the 3/8” nap roller into the mixture coat the roller head then roll off any excess into the paint tray avoiding liquid build-up on the sides of the roller caps and/or the frame. Avoid dripping Smith’s Hi-Wear 90S during placement on the floor as the metallic fillers will concentrate in the drip and may not evenly disperse while finishing the coating.DO NOT ATTEMPT TO PART MIX KITS

-

Safety Data Sheet | SDS | Part A

Download PDFSafety Data Sheet | SDS | Part B

Download PDFSafety Data Sheet | SDS | Part C

Download PDFTechnical Data Sheet | TDS

Download PDFVisit Smith's Website

Visit Website